High Flexibility SMT Line for Efficient Electronics Assembly | SMT Machine

Tailored Turnkey SMT Line Solution for Diverse Industries

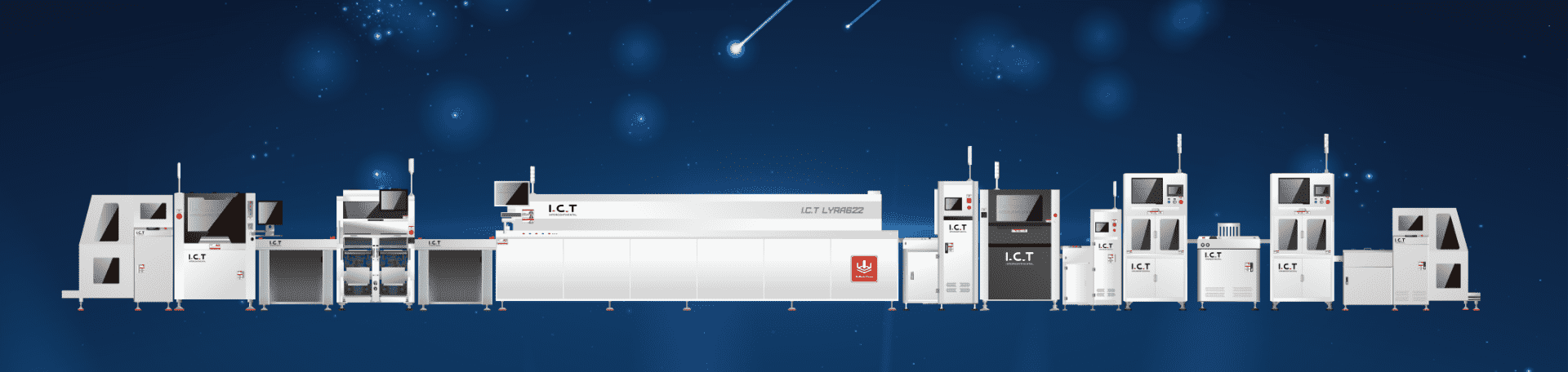

At I.C.T, we specialize in delivering complete Turnkey SMT line solution designed to streamline your manufacturing processes. Our comprehensive services encompass SMT assembly, PCBA coating, DIP (Dual In-line Package) insertion, semiconductor handling, and more. With a focus on customization, we excel in designing optimized layouts and providing on-site technical support to ensure seamless integration of our solutions into your operations.

Applications Across Varied Industries

I.C.T SMT production line is utilized across a broad spectrum of industries, including:

- Automotive Electronics: Precision and reliability for vehicle components.

- Medical Devices: Meeting stringent quality standards for healthcare equipment.

- Power Systems: Enhancing efficiency and performance in energy solutions.

- LEDs: Advanced assembly for lighting technologies.

- Smart Security: Integration of electronics for surveillance and access control.

- Aerospace and Defense: Meeting aerospace-grade requirements for mission-critical applications.

- Smart Home Appliances: Electronics integration for connected home solutions.

- Consumer Electronics: High-volume production with consistent quality.

Electrical Power System

U-shaped SMT Line

- U-shaped design seamlessly connects DIP and PCB Assembly line for enhanced efficiency.

- Two PCB Turn Conveyor ensure smooth material flow and reduce production bottlenecks.

- Customizable production line specifications and production capacity to meet customer needs.

Automotive Electronics

Turnkey SMT Line

- High Precision Placement: Equipped with dual JUKI RS-1R machines for precise component placement.

- Efficient Soldering: Includes an inline selective soldering machine to ensure reliable soldering.

- Optimized for Quality and Efficiency: Designed to deliver high-quality production with optimal efficiency.

Smart Security

Full-Auto SMT Assembly Line

- PCB stacker boosts production efficiency and space utilization.

- Reliable medium-speed SM482 pick and place machine handles high-precision component mounting.

- NG/OK unloader automatically identifies defective products, improving production efficiency.

Communication Industry

Fully-auto SMT Line Solution

- High Flexibility SMT line tailored to the special needs of communication equipment manufacturing.

- JUKI RX-7R pick and place machine, reflow oven, SMT AOI ensure high production quality and efficiency.

- Suitable for assembling PCB of various communication devices.

LED Industry

Full-auto LED Production Line

- The LED production line caters to customer’s 1.5-meter LED product manufacturing requirements.

- Seamless material flow from 1.5-meter vacuum loader to 1.5-meter cooling buffer machine.

- High production capacity of 120pcs/hour ensures fast and efficient output.

Smart Home Appliance

Fully-auto SMT Line

- Two customized SMT assembly line.

- One SMT line assembles LED beads on circuit boards, while the other SMT production assembles LED lens.

- Ultimately used for producing TV backlight bars (LED Bars).

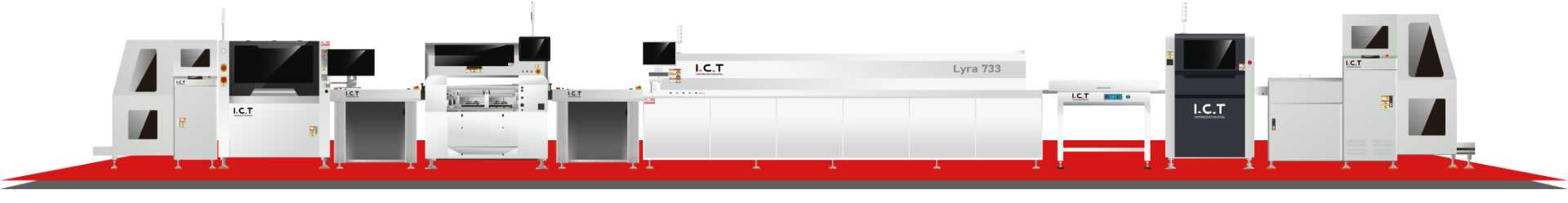

Basic: Standard Fully Automatic SMT Production Line

This essential yet highly practical SMT production line includes a fully automatic printer, pick and place machine, reflow oven, loader and unloader, and conveyor. It is ideal for basic EMS company production needs.

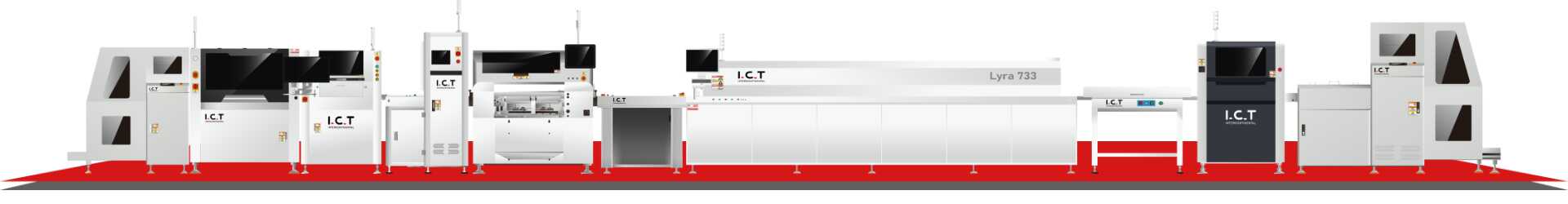

Advanced: PCB Assembly Line with Higher Yield Rates

Enhance your product quality with our advanced PCB assembly line, featuring SPI for solder paste inspection, AOI for solder joint inspection, and X-ray for BGA inspection. Ensure superior performance and higher yield rates.

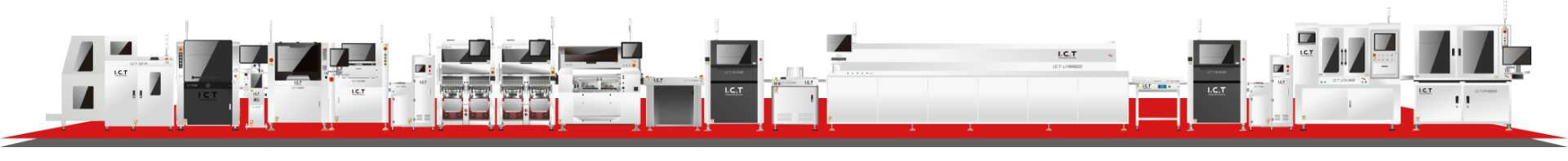

Premium: Fully Automated Traceable High Flexibility SMT Line

With the addition of traceability equipment, you can identify the source of each PCB. This line includes a laser marking machine, inkjet marking machine, and label mounter to ensure complete traceability.

I.C.T Sets High Service Standards

A Reference in One-Stop Service Excellence

Pre-sales Support

Guidance for well-informed decisions.

- Solutions & Processes

- Technical analysis & Reasonable suggestions

- Required output

In-sales Support

Seamless experience -effortless, successful.

- Confirm system

- Quality Assurance: Rigorous Standards

- Technical & function test sheet

After-sales Support

Take support to the next level of excellence.

- Online & offline technical support and training

- Reply in seconds

- Solve problem first

From A to Z Turnkey SMT Line Solution

Helping You Achieve Seamless Integration and Optimal Efficiency

On-Site Installation and Training Expertise

What you will get

Count on I.C.T’s overseas SMT engineers to visit your facility, ensuring precise equipment setup, thorough debugging, and comprehensive training for your operators. Our commitment extends until your first PCBA production confirms training completion.

Why Choose I.C.T to Build Your Factory

For nearly 20 years, I.C.T has been dedicated to providing comprehensive SMT solution to our valued customers. With extensive industry experience and a team of dedicated professionals, we tailor flexible and efficient production lines and PCB assembly line to meet your specific product, requirement, and budget needs.

I.C.T’s State-of-the-Art Manufacturing Facility

The I.C.T factory is a modern facility with 89 staff members, spanning 12,000 square meters and backed by a $20 million investment. We employ 13 service engineers, operate 3 overseas warehouses, and have invested in 8 factories.