| Item | Model | I.C.T-910 |

| Transmission system | Efficiency of the machine | Standard machine: Equipped with universal burner of Puro and other brands: 8 sets of 32-64sit burners: UPH 2000-3000PCS/H; Equipped with 204AP brand universal burner: 3 sets of 12sit burners: UPH1600-2200PCS/H |

| A small number of diverse modes: equipped with 3 sets of 204A burners, UPH 1600-1800PCS/H. |

| Packaging conversion mode: pallet to tape production capacity of 4000PCS/H (12mm tape products as an example) |

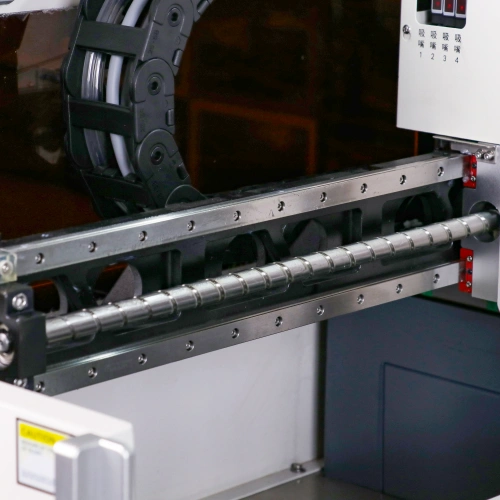

| Control precision | Precision servo screw drive, accuracy: X-axis ±0.015mm; Y-axis ±0.015mm; Z-axis ±0.03mm; P-axis ±0.03mm; U(θ)-axis ±0.15° |

| Suitable package form | PLCC, JLCC , SOIC, QFP, TQFP, PQFP, VQFP, TSOP, SOP, TSOPII, PSOP, TSSOP, SON, EBGA, FBGA, VFBGA, BGA, CSP, SCSP, and so on. (Open Top adapters, some ICs need to be customized with special adapter consumables). |

| Includes precision upper and bottom CCD positioning system. |

| Feeding and unloading device | Tray IN/ OUT | Supports automatic Tray feeding, can send 10 trays of JEDEC Tray products at the same time, and supports marking tray components after programming |

| Tube IN/ OUT | Support 4-tube IC electromagnetic vibration feeding |

| Tape IN/ OUT | Electric feeder, supports 8-24mm self adhesive film or hot press packaging. |

| Conversion of packaging methods | Different packages are converted to each other, Tray packed to Tape packed, Tape packed to Tray packed. |

| Other | Nozzle | 4pcs |

| Camera | 2pcs (Component camera + Marking camera) |

| Feeder station | 2pcs (8-24mm) |

| Ion fan | 2pcs |

| Power | Operating voltage: 190~240V/50Hz, 2.0KW |

| Dimension | L1450*W860*H1450mm |

| Weight | 700kg |