Wave Soldering & Selective Soldering

Wave Soldering machine & Selective wave Soldering machine are essential pieces of equipment in the (Through-Hole Technology) THT Line. The THT Line plays a crucial role in the assembly and manufacturing of electronic devices, where components with leads are mounted onto PCB through holes drilled into the board. This technology is indispensable in various industries, including automotive, aerospace, consumer electronics, and telecommunications, where reliability and durability of electronic assemblies are paramount. The precision and efficiency provided by wave and selective soldering machine ensure high-quality solder joints, making them vital for the production of robust electronic products.

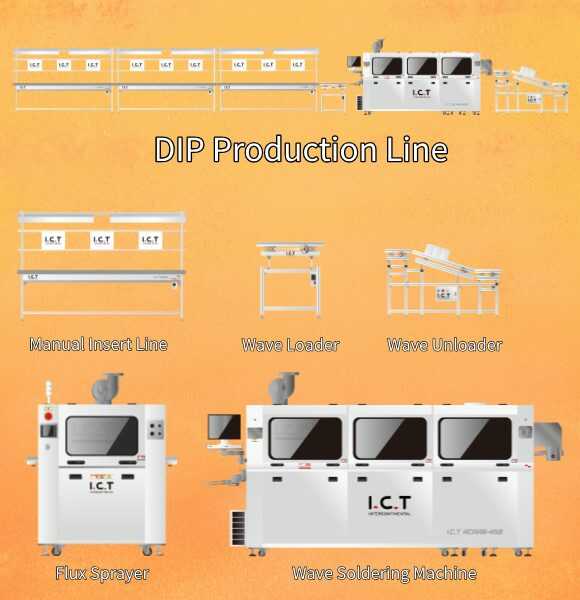

DIP Line in Electronics Manufacturing

The DIP Line (THT Line) is an indispensable production line in the electronics industry. It includes essential soldering equipment such as wave soldering machine, selective soldering machine, and flux spray machine.

Additionally, the line features manual insertion line and fully automatic insertion machine. To ensure the quality of DIP component soldering, AOI machine is also incorporated.

The Role of THT Line in Electronics Manufacturing

In the electronics field, the THT Line is one of the indispensable production lines. Typically, it is preceded by a SMT production line and followed by a Conformal Coating Line. In modern electronics, the SMT production line has not replaced the THT production line despite the miniaturization of components. This is because of the essential DIP (Dual In-line Package) components that require through-hole mounting. The normal production process involves the SMT production line first, followed by the THT production line, and finally, the Conformal Coating Line, which applies a protective coating to enhance the longevity of the PCBA (Printed Circuit Board Assembly).

Composition and characteristics of DIP line

The DIP line offers various solutions tailored to the specific needs of our clients. The final setup is determined based on several factors, including the nature of the client’s products, budget constraints, production capacity, and the required soldering precision. Our goal is to provide a customized approach that meets each client’s unique requirements effectively.

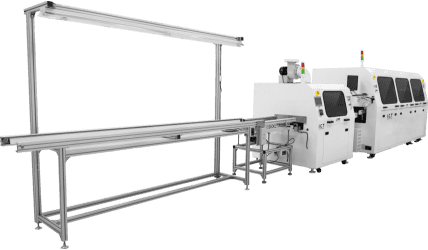

DIP Line Solution 1 With Wave Solder Machine

This is a basic DIP line, comprising essential equipment such as wave soldering machine. I.C.T offers two series: the compact W2 and the high-performance Acrab350.

The line begins with a 3-meter or 6-meter manual insertion line, typically requiring 1-2 workers per meter. For a 3-meter line, around 5 workers will insert DIP components into the PCBs before they proceed to the Lead Free Wave Solder Machine for soldering.

As an expert, you know that uniform flux spraying before soldering is crucial for optimal results. If you are concerned about the flux spraying capability of the Lead Free Wave Solder Machine, you can choose an independent flux sprayer. After wave soldering, the PCB move to the belt assembly line. This is the general workflow. Personnel required: 5-20 people, adjusted according to the product.

Advantages:

- Cost-Effective: Suitable for small-scale production.

- Flexibility: Easily adjustable to meet varying production needs.

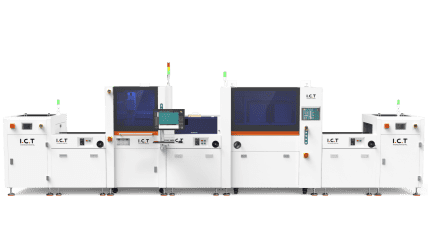

DIP Line Solution 2 With Selective Soldering Machine

This is a more advanced DIP line, typically used in high-end fields such as aerospace for manufacturing satellite radars, automotive electronics for producing battery protection boards and central control screens, and the medical field for circuit boards in MRI or CT machines.

The core equipment in this production line is the selective wave soldering machine. Before the selective soldering machine, there is a fully automatic insertion machine, which helps to improve efficiency and reduce errors that may occur with manual operations.

After the selective wave soldering machine, there is an AOI specifically for DIP soldering, ensuring that the soldered PCBA is thoroughly inspected to minimize defective products. Personnel required: 1-3 people.

Advantages:

- High Automation: Ideal for efficient large-scale production.

- Efficiency: Maintains high-quality standards with minimal human intervention.

Wave Soldering Machine Selection Ensuring High Capacity, Precision, and Soldering Quality

I.C.T-W2

– PCB width: 60 – 350 mm

– Solder pot capacity: 250 kg

– Preheating zones: 1pcs

– Preheating length: 900 mm

– Size: 2900 x 1160 x 1500 mm

– Weight: Approx. 790 kg

Acrab 450

– PCB Width: 50 – 450 mm

– Solder pot capacity: 500 kg

– Preheating zones: 3 pcs

– Preheating length: 1800 mm

– Size: 4420 x 1520 x 1750 mm

– Weight: Approx. 1900 kg

Selective Soldering Machine Selection Stainless steel with Japan SURF process and Germany Jet Valve for spot and line spraying.

I.C.T-SS430

– PCB Max Size: 500*500mm

– Preheating Mode: IR Heating

– Preheating Area: 500*500mm

– Solder Pot & Nozzle: 1 set

– Double Pot: N/A

– Solder Capacity: 11Kg

– Size: L1400*W2580*H1722mm

– Weight: Approx. 700 kg

I.C.T-SS550

– PCB Max Size: 500*500mm

– Preheating Mode: Hot air and IR

– Preheating Area: 500*500mm

– Solder Pot & Nozzle: 1 pcs

– Double Pot: Option

– Solder Capacity: 11Kg

– Size: L2560*W1750*H1480

– Weight: Approx. 1200 kg

I.C.T-SS540

– PCB Max Size: 500*500mm

– Preheating Mode: Hot air and IR

– Preheating Area: 500*500mm

– Solder Pot & Nozzle: 1 pcs

– Double Pot: N/A

– Solder Capacity: 11Kg

– Size: L1750*W1750*H1480mm

– Weight: Approx. 800 kg

I.C.T-SS550P1

– PCB Max Size: 500*500mm

– Preheating Mode: Hot air and IR

– Preheating Area: 500*500mm

– Solder Pot & Nozzle: 2 set

– Double Pot: Option

– Solder Capacity: 11Kg

– Size: L2560*W1950*H1480

– Weight: Approx. 1300 kg

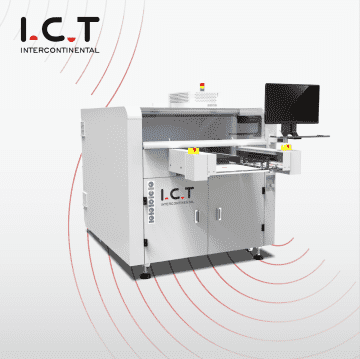

Automatic Insertion Machine Selection Axial, Radial and Odd Form Automatic Insertion Machine, Enhancing Efficiency and Accuracy in PCB Assembly

Auto Insertion Machine

– Axial Insertion Machine

– Radial Insertion Machine

– PCB Pin Insertion Machine

Odd-Form Inserter

– Supports Component Insertion: IC, Capacitor, Tact Switch, VGA, Pin Module, Transformer, USB, Connector, Coil.

– Modular Design: Allows flexible adjustment of production lines to meet manufacturing needs.

AOI Machine Selection Ensuring Quality Assurance with Advanced Inspection Technology

I.C.T AI-4026

– Efficiency: Designed for DIP component inspection, integrates into manual lines.

– Streamlined Process: Identifies pre-soldering issues, ensuring smooth production and reducing post-soldering challenges.

AI-5146W

– Designed for post-wave soldering, scrutinizing solder joint quality.

– Dual CCD units inspect both sides of PCBA simultaneously.

– Equipped with Deep Learning Algorithm, Flexible Procedures, and rapid programming.

Applications of THT Line

Customer Success Cases

An industrial control systems manufacturer implemented I.C.T’s THT Line, achieving a 30% increase in production efficiency and a 20% reduction in defect rates. This improvement has enabled the company to meet higher demand while maintaining superior product quality.

Mining Equipment Manufacturer

A mining equipment manufacturer adopted I.C.T DIP Line, resulting in a 25% boost in production speed and a 15% decrease in production costs. The enhanced efficiency has allowed the company to scale operations and deliver more reliable products to their clients.

An automotive electronics manufacturer integrated I.C.T’s Assembly Line into their production process, leading to a 35% improvement in production efficiency and a significant reduction in component failure rates. This advancement has strengthened their product reliability, crucial for withstanding the harsh conditions of automotive environments.

Diverse Industry Partnerships

Discover I.C.T esteemed partners across EMS, LED, automotive electronics, aerospace, fire safety, and more, all leveraging high performance Wave Soldering and Selective Soldering technology. Each logo showcases our commitment to advancing innovation and precision in manufacturing processes.