Consult with Us Today

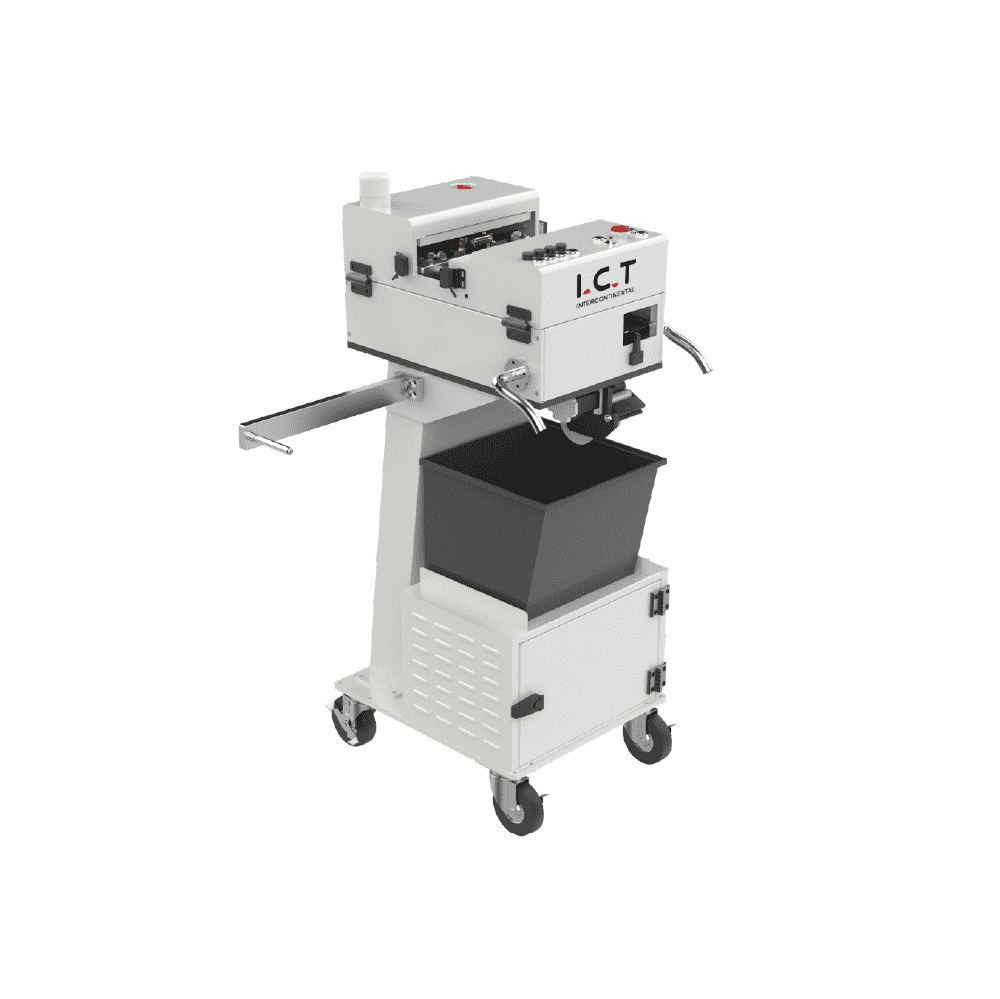

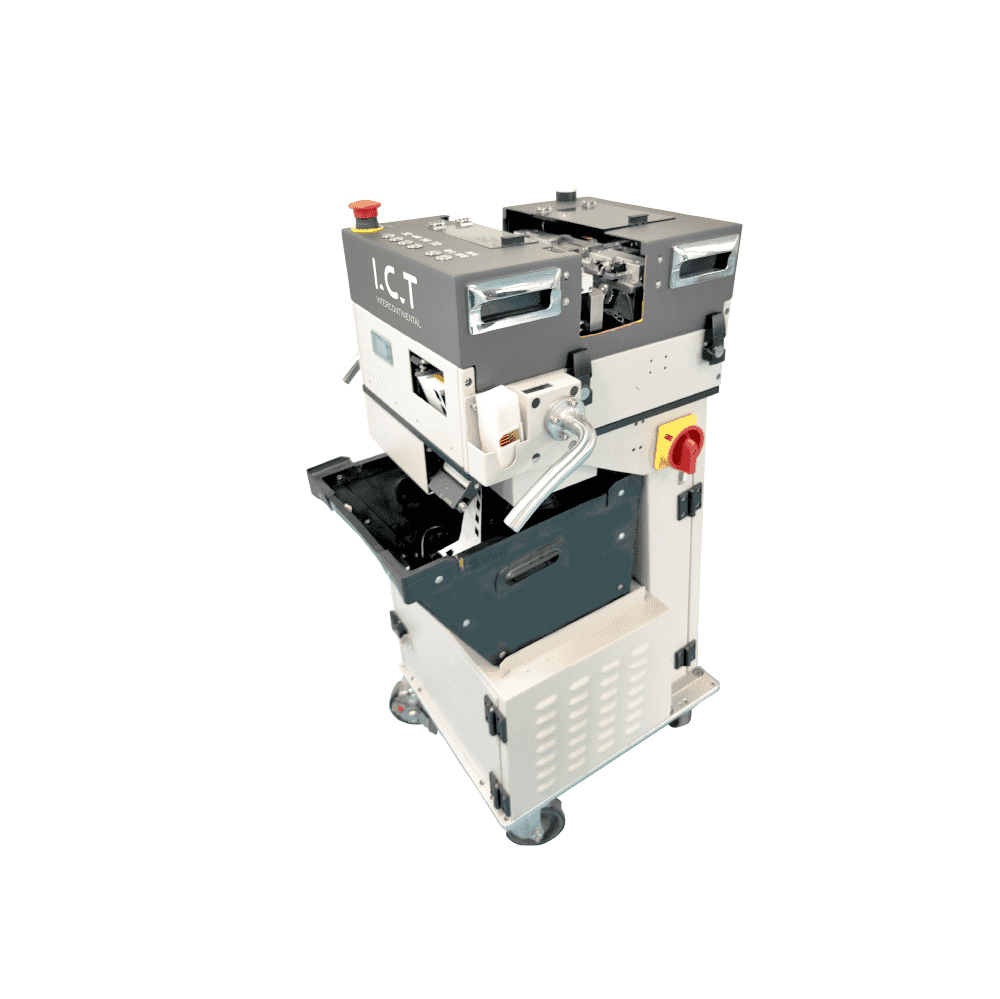

I.C.T offers adaptable SMT solutions for diverse needs. Our top-notch service, online support, and cutting edge engineering ensure high quality processes. Committed to excellent service, we maximize production line productivity with outstanding quality driven by lean processes, employee integration, proactive planning, and continuous improvement.

Your Free Professional Consultation

By consulting with us today, you can receive one hour of free online professional consultation with a top-tier SMT engineer with 24 years of experience. Don’t miss this opportunity to enhance your production efficiency and quality!