Pick and Place Machine

Efficient and Precise SMT Pick and Place Machine

JUKI SMT Pick and Place Machine

Surface Mount Technology (SMT) component placement systems are commonly referred to as SMT pick and place machine or SMT chip mounter.

When using JUKI pick and place machine to mount your SMD components onto PCB, we guarantee exceptional precision and high speed.

The RS-1R SMT machine is well-known for its capability to place a diverse range of chip components. It features various SMD mounting heads and P&P nozzles, ensuring accurate placement even for the smallest components.

JUKI Pick and Place Machine Bringing tomorrow's electronics to life

RS-1R Model:

Unmatched Speed: Capable of placing up to 47,000 components per hour

Advanced “Takumi Head”: Features an adjustable recognition sensor height

Superior Line Balance: Ensures the highest throughput

Broad Component Compatibility: Handles sizes from 0201 metric to large connectors and ICs

Perfect for LED Placement: Optimized for precise LED assembly

What Is a SMT Pick & Place Machine?

SMT pick & place machine is vital tool in modern manufacturing, especially in electronics, semiconductors, and PCB assembly. They automate the precise placement of electronic components onto printed circuit boards (PCBs), ensuring accuracy and efficiency in the production process.

- Importance of SMT pick & place machine

- How SMT Pick & Place Machine lmprove Production Effciency

- How to Choose a SMT Pick & Place Machine

Precision and Accuracy: They handle electronic components with exceptional precision, ensuring that every piece is placed correctly. This guarantees the reliability and functionality of the final product.

Speed and Efficiency: Operating at high speeds, these machines make rapid and consistent component placement possible, which is vital for high-volume manufacturing.

Versatility: They can accommodate a wide variety of component types, sizes, and orientations. This versatility allows us to adapt to diverse production needs without major adjustments.

Labor Reduction: By automating the placement process, SMT pick & place machine significantly reduce labor costs. They also minimize the risk of human errors or mistakes caused by fatigue, ensuring a more reliable production process.

Versatile SMT Placement Machine Series

Our versatile SMT placement machine series offers unmatched flexibility and precision, capable of handling a wide range of components and production needs. Designed for efficiency and reliability, these machines are perfect for various manufacturing applications.

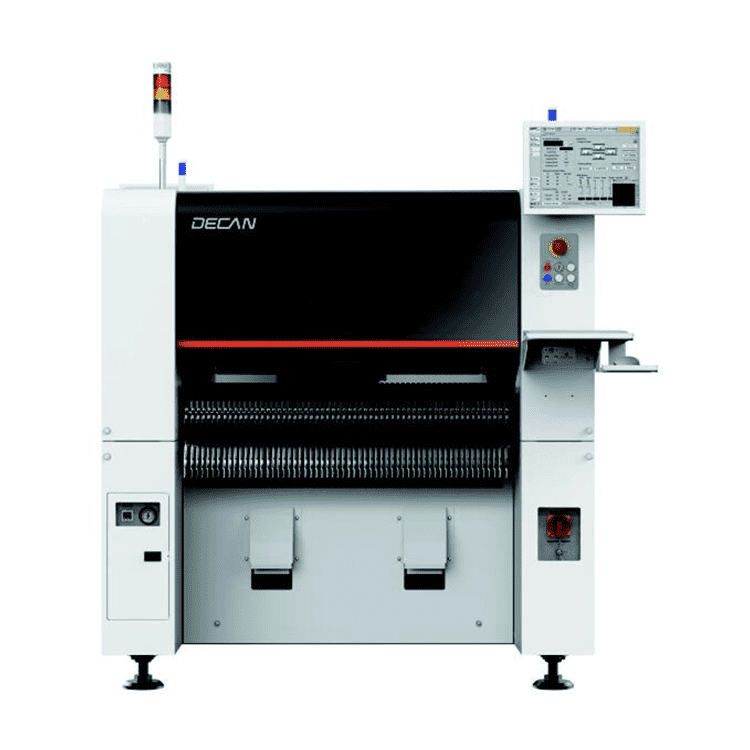

Flexible SMT Machine A versatile SMT placement machine designed for small to medium production volumes, capable of handling a wide variety of components and quick changeovers

JUKI RX-1R

Hanwha Decan S2

Hanwha SM481plus

PANASONIC NPM-TT2

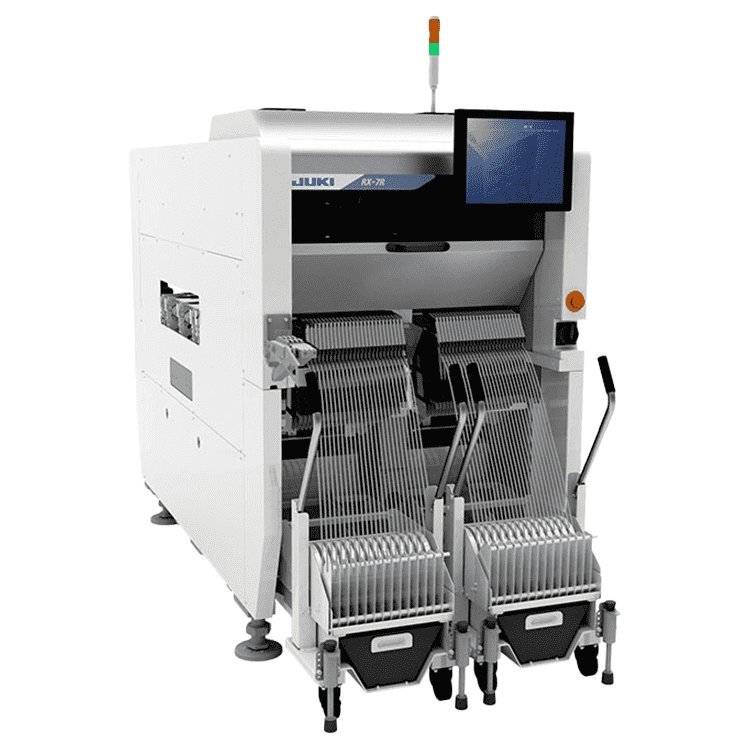

High Speed SMT Machine A high-efficiency SMT placement machine optimized for large-scale production, emphasizing rapid throughput and precision placement

Hanwha SM471plus

Hanwha Decan L2

JUKI RX-7R

JUKI RX-8

SMT Peripheral Machine Supporting equipment in SMT product processes, enhancing overall production efficiency and quality. Such as SMD Tape Splicing Machine, Intelligent SMD Storage System, SMD X-Ray Counter

SMD Tape Splicing Machine

I.C.T-AISM08

SMD tape splicing machine offers unparalleled versatility, accommodating material belts ranging from 4 to 72mm, ensuring comprehensive coverage for diverse production needs. With its intuitive interface, operators can become proficient in just 5 minutes, reducing dependency on specialized personnel and optimizing workforce utilization.

This machine significantly boosts efficiency for SMT chip mounter, preventing production line stoppages that could lead to substantial losses in production opportunities. By ensuring continuous operation, it maximizes productivity and minimizes downtime, safeguarding your manufacturing process against costly interruptions.

Intelligent SMD Storage System

I.C.T ISS-2000

I.C.T’s SMT Intelligent SMD Storage System, also called SMD Tower, an essential component of the cutting-edge smart factory infrastructure. Designed to revolutionize SMD component storage, this system seamlessly integrates cloud management, intelligent operation, and refined management techniques. It is engineered to optimize efficiency and productivity throughout the storage process, from component loading to unloading and replenishment. With a focus on streamlining operations and enhancing overall production efficiency, this innovative solution offers a host of advanced features.

SMD X-Ray Counter

I.C.T-XC3100

The I.C.T Offline SMD X-Ray Counter is renowned for its exceptional precision, boasting an impressive accuracy rate of 99.99% for 0201 components and adeptly handling even the smallest 01005 components. With a rapid pointing speed of approximately 6-10 seconds per four plates, it ensures efficient counting processes. Leveraging advanced X-ray imaging technology, it efficiently detects production materials using AI algorithms, swiftly capturing image information for precise counting. Seamlessly integrating with factory ERP/MES systems, it enhances workflow efficiency, making it a valuable asset for warehouse management and beyond.

STRONG AND RELIABLE SERVICE SUPPORT

I.C.T’s team of 10 overseas engineers is our key strength. They have deep expertise in our equipment and excel in post-purchase support. From the moment you inquiry our SMT chip mounter, our engineers are available to answer your questions, ensuring a response within 2 hours and resolution on the same day. This dedication guarantees you continuous support and satisfaction.

Comprehensive Technical Support for Every Stage

Our technical support services ensure a seamless and successful experience from start to finish.

Pre-sales Support: We provide expert guidance to help you make well-informed decisions, offering technical analysis and reasonable suggestions tailored to your needs.

In-sales Support: Enjoy a seamless and effortless experience with our in-sales support, including system confirmation, rigorous quality assurance, and comprehensive technical and functional testing.

After-sales Support: Elevate your support experience with our exceptional after-sales service. We offer both online and offline technical support and training, with rapid response times to promptly address and resolve any issues.